Corporate News

Corporate News

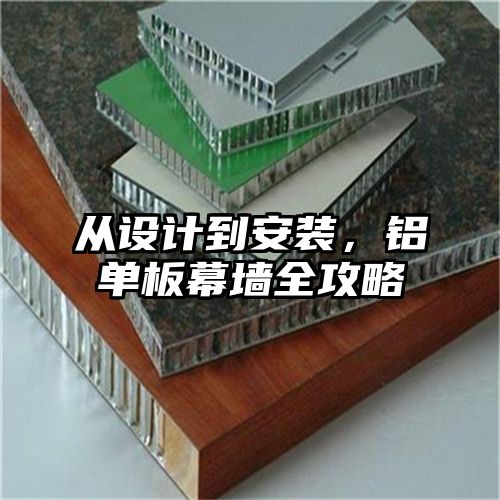

With the development of construction industrialization, modern aluminum veneer curtain walls are becoming increasingly popular. Compared to traditional brick and concrete structure walls, aluminum veneer curtain walls have advantages such as lightweight, energy-saving, waterproof, and convenient construction. It can not only achieve the freedom of opening windows on exterior walls, but also create various visual effects. So what is the construction process of aluminum veneer curtain wall from design to installation? Let's take a look at the complete strategy of aluminum veneer curtain wall together.

1. Determine the function of the wall

Firstly, it is necessary to clarify whether the main function of the curtain wall is lighting, smoke exhaust, ventilation, or decorative curtain wall. Curtain walls with different functions will vary in material selection and structural design.

2. Design the wall to withstand wind loads

Scientifically design the wind load that the wall structure needs to withstand based on the wind environment and building height in the project area. At the same time, the self weight of the wall and other additional loads should be considered.

3. Coordinate with the layout of the building structure

The curtain wall design should be coordinated with the overall structural layout of the building and should not affect the safety of the building structure. To determine the strength of wall materials and the design of connection parts based on this.

4. Wall window design

The position and size of the window directly affect the lighting and ventilation effect. Window design should consider multiple requirements such as functionality, aesthetics, and wall strength.

5. Wall decoration effect

The visual effect of the curtain wall can be presented through aluminum panels of different materials and colors, as well as surface treatments. We need to comprehensively consider factors such as styling, budget, and construction difficulty.

1. Installation of wall mesh

Firstly, based on the structural drawings, determine the location of the wall and divide it, and then install the wall grid on site. To ensure accurate and secure positioning of the grid to support the installation of subsequent wall panels.

2. Installation of pre embedded parts

Mark the position of the embedded parts installed according to the diagram on the axis network. The embedded parts mainly include window sleeves, diagonal supports, etc. These embedded parts are key components that connect the wall panels to the main building.

3. Wall panel installation

After modifying the wall panel to size, it can be lifted into place manually or by lifting equipment, and fixed by inserting embedded parts. The surface of the wall panel should be kept clean to avoid damage.

4. Strengthen the support system

In addition to embedded parts, reinforcement components such as L-shaped aluminum corners and waist supports need to be installed to ensure that the wall panels are firmly connected to the building and can withstand wind loads.

5. Install sealing strips and silicone

Waterproof sealing strips should be used to fill the joints of wall panels and between windows and doors to ensure the waterproofing of the wall. And finally apply silicone plaster treatment to enhance the wall decoration effect.

6. Debug the window opening system

After opening the window with purlins, it is necessary to immediately debug and check whether the mechanical components such as pulleys operate flexibly. And ensure good sealing performance.

7. Cleaning and maintenance

After construction is completed, cleaning should be carried out to remove dirt and construction marks, and the wall should be maintained. Do not stack items on newly installed walls to avoid damage.

1. Strictly follow the construction drawings and do not arbitrarily change the position of embedded parts.

2. When lifting wall panels, be careful and handle them gently to prevent surface damage.

3. The tightening of connecting bolts should meet the design requirements and should not be too loose or too tight.

4. The joints between the wall panels should be smooth and aesthetically pleasing. When filling the sealing strip, no gaps should be left.

5. When debugging the window, be careful and check its sealing function. Do not mount heavy items.

6. Take good edge protection measures to prevent construction personnel from falling.

7. Before delivery of the project, the wall should be cleaned properly and no stains should be left.

8. Avoid stacking materials on new walls and gradually remove and store them.

Through scientific design and standard construction processes, the quality of aluminum veneer curtain wall engineering can be ensured. It not only enhances the appearance of buildings, but also strengthens their functions, making it an indispensable part of modern architecture. I hope the above content can provide you with some reference in the construction of aluminum veneer curtain walls. If you have any other questions, please feel free to continue communicating!