Industry information

Industry information

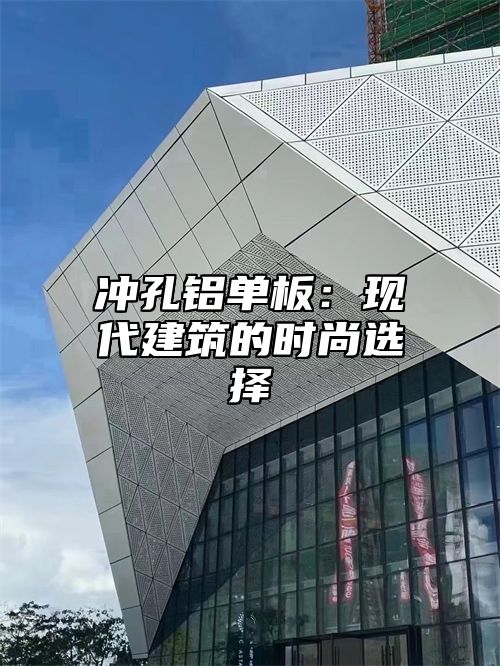

Ladies and gentlemen, today let's talk about an indispensable element in modern architecture - perforated aluminum veneer! You may often see it in high-end buildings, shopping centers, or office buildings, but do you know the story behind it? Let me take you to unveil the mysterious veil of punched aluminum veneer.

We need to talk about the name punched aluminum veneer. Does it sound a bit high-end? It is a decorative material made by punching aluminum plates. After special processing, the aluminum plate forms various patterns and holes, presenting a unique visual effect.

Speaking of which, you may ask, why do modern buildings like to use punched aluminum veneers? We have to start with its advantages.

Punched aluminum veneer has the characteristics of lightweight and high strength. Aluminum material itself has a low density, coupled with special punching technology, making it both lightweight and sturdy. In this way, the application of perforated aluminum veneer in construction can reduce the weight of the building and lower construction costs.

Punched aluminum veneer has excellent weather resistance. It can maintain good performance regardless of wind and rain, or exposure to sunlight and rain. This has made it widely used in outdoor buildings, such as curtain walls, billboards, sunshades, etc.

Punched aluminum veneer has rich colors and diverse patterns. From simple lines to complex patterns, it can almost meet the needs of all designers. This makes it a beautiful scenery in modern architecture.

How is punched aluminum veneer made? Here we need to mention an important process - CNC punching. It is to use computer control punching machine to punch holes according to the preset pattern and hole size. This process may seem simple, but it requires precise craftsmanship and equipment.

In the production process of punched aluminum veneer, there is also a key process - surface treatment. Through surface treatment, the corrosion resistance, weather resistance, and aesthetic appearance of aluminum veneer can be improved. Common surface treatment methods include fluorocarbon spraying, spray painting, baking paint, etc.

The application fields of punched aluminum veneer are also very extensive. In addition to the construction field we just mentioned, it is also widely used in industries such as furniture, decoration, and transportation. Some high-end furniture uses perforated aluminum veneer on the surface, which is both beautiful and practical.

I want to share a little story. Once, I saw a building in a shopping center whose exterior walls were decorated with perforated aluminum panels. The unique patterns and holes made me stop and admire them. When I walked into the mall, I found that the goods inside were dazzling and overwhelming. At this moment, I suddenly realized that punched aluminum veneer is not only a part of architecture, but also a witness to modern life.

Everything has two sides. Punched aluminum veneer is no exception. During use, we need to pay attention to the following points:

During the installation process, it is necessary to ensure that the gap between the aluminum veneer and the wall is tight to avoid rainwater infiltration.

2. The surface treatment should be kept clean to avoid stains and scratches.

3. Regularly check the fixing condition of aluminum veneer to ensure safety.

Punched aluminum veneer, as a modern building decoration material, has many advantages. In the future, it will play an increasingly important role in fields such as architecture, decoration, and furniture. Let's look forward to the surprise that punched aluminum veneer will bring us together!