Industry information

Industry information

Ladies and gentlemen, let's talk about the new darlings quietly emerging in the construction industry - perforated aluminum veneer! As soon as this thing appeared, it carried a fashionable vibe that was eye-catching. Let's start with a definition: punched aluminum veneer, which is a sheet made by punching aluminum plates through special processes. Does it sound a bit high-end?

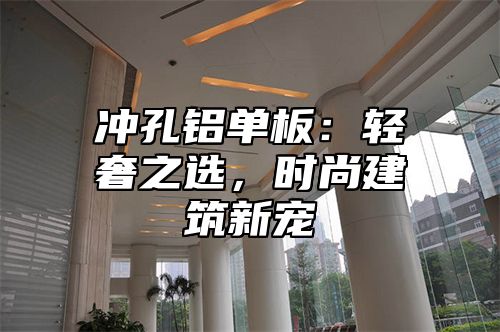

Imagine a skyscraper with a simple yet sophisticated appearance, its smooth surface with a unique texture that is irresistible to take a few more glances at. This is the charm of punched aluminum veneer. It not only satisfies our pursuit of beauty, but also hides many secrets that you may not know.

We need to talk about the "light luxury" attribute of this punched aluminum veneer. Why is it called 'light luxury'? Because this type of board is both low-key and meaningful. Its material is aluminum, which we all know is a lightweight and corrosion-resistant metal. When used in buildings, it not only reduces the weight of the building but also enhances its durability. The punching design gives the aluminum plate a more layered visual effect, as if it can emit a luxurious luster in the sunlight.

I remember one time, I visited a newly built office building and the appearance of the punched aluminum veneer really impressed me. I stood downstairs, looking up as if I could feel it breathing. That feeling is like wearing an exquisite dress, both fashionable and high-end.

Punched aluminum veneer is not only for aesthetics, but its practical value should not be underestimated. It has excellent sound insulation effect. Those holes are like small ears that can effectively absorb external noise, making the indoor environment quieter and more comfortable. Punched aluminum veneer also has excellent heat dissipation performance. In summer, it can help lower the temperature inside buildings and reduce air conditioning energy consumption.

Let's talk about the installation of punched aluminum veneer again. This thing is really convenient and fast to install. Its size and thickness can be customized according to requirements, which can better adapt to various architectural styles. Punched aluminum veneer uses a special adhesive to firmly adhere to the wall, ensuring safety and facilitating disassembly and maintenance.

At this point, I couldn't help but recall a story. That's a friend of mine abroad who told me that many buildings in their country use punched aluminum veneer. Once, a landmark building in their city had an accident that required urgent repairs. As a result, the construction team completed the repair work in just one day, thanks to the convenience and efficiency of punching aluminum veneers.

Everything has two sides. There are also some things to pay attention to when using punched aluminum veneer. To avoid surface oxidation of aluminum plates, regular cleaning and maintenance are necessary. When choosing perforated aluminum veneer, attention should also be paid to its quality to avoid affecting the overall effect of the building.

Punched aluminum veneer, as a new type of building material, has become a new favorite in the construction industry due to its unique charm and practical value. It not only makes our buildings more beautiful and elegant, but also brings us a more comfortable living environment. Perhaps in the near future, punched aluminum veneer will become an indispensable part of our lives.

I have a question for everyone: If you were asked to choose building materials, would you prefer punched aluminum veneer? Welcome to leave a comment in the comment section to share your thoughts!