Industry information

Industry information

Dear aluminum veneer enthusiasts, today let's talk about a familiar and mysterious building material - punched aluminum veneer. You may use this thing every day, but do you know the story behind it? Don't worry, let's unveil this mysterious veil together.

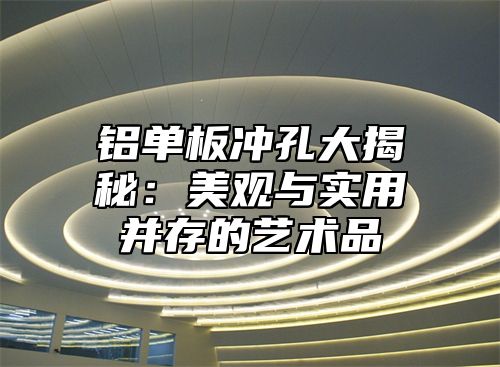

We need to talk about what punched aluminum veneer is. It is a common building material in our daily lives, which is made by punching various patterns or holes on aluminum plates, and then surface treatment and installation. This thing may seem simple, but it has many uses, such as building exterior walls, indoor ceilings, billboards, and so on.

Speaking of which, you may ask, 'What's special about punched aluminum veneer?' There are quite a few. It is beautiful and elegant, with various patterns and hole designs that make the building more personalized. If you don't believe me, take a look at those high-end office buildings and shopping malls. Which one is not beautifully decorated with aluminum veneer?

Punched aluminum veneer also has excellent weather resistance and corrosion resistance. We all know that aluminum is a lightweight metal with excellent corrosion resistance. And punching treatment can make the aluminum plate better resist wind and sun exposure, extending its service life. Isn't this what we want for 'durability'?

Let's talk about its practicality again. Punched aluminum veneer can be customized in various sizes and patterns according to requirements to meet the needs of different occasions. You can imprint the company logo on the ceiling of the office, making corporate culture ubiquitous; Fashion patterns can also be printed on the exterior walls of shopping malls to attract customers' attention.

Punched aluminum veneer is not without its drawbacks. It has a relatively high price and a complex installation process. Its advantages far outweigh its disadvantages, so its presence can be seen in many occasions.

How is punched aluminum veneer made? There is a lot of knowledge behind this. Choose the appropriate aluminum plate material. Aluminum alloy plate is the best choice because it has good plasticity, corrosion resistance, and strength. According to the design requirements, various patterns and holes are punched out on the aluminum plate. This process requires precise equipment and craftsmanship to ensure consistent hole size and clear patterns. Surface treatment of punched aluminum plates, such as spraying, oxidation, etc., to increase their aesthetics and durability.

Speaking of which, I would like to share a little story. Once, I saw a building on a construction site where punched aluminum panels were being installed. The workers were busy carrying and installing, and the scene was quite spectacular. I suddenly thought that these aluminum panels will become a part of this building in the near future, witnessing the changes of this city. This makes me exclaim: Punched aluminum veneer is truly the crystallization of human wisdom!

The application fields of punched aluminum veneer are far beyond these. In the future, I believe it will continue to exert its unique charm and bring more beauty to our lives.

What I want to say is that although perforated aluminum veneer is beautiful, it should also be used reasonably. After all, this thing is expensive, and we should cherish every aluminum plate to maximize its value.

Punched aluminum veneer is a building material that is both aesthetically pleasing and practical. It not only makes our buildings more personalized, but also brings us more convenience. Let's look forward together, punched aluminum veneer will create more beauty for us in the future!