Industry information

Industry information

Friends, have you ever thought about what makes tall buildings shine so brightly behind them? I'm here to reveal to you - fluorocarbon aluminum veneer!

It must be said that the name fluorocarbon aluminum veneer sounds quite high-tech, but in fact, it is a type of aluminum veneer. It adopts fluorocarbon coating for surface treatment, which not only has strong durability, but also is waterproof and moisture-proof. How about it, doesn't it sound very stylish?

Speaking of fluorocarbon aluminum veneer, I would like to share an interesting story with everyone. Once, a friend and I who were doing decoration went to observe on site. That day, the sky was blue and the sunshine was just right. My friend pointed to a high-rise building that was being installed and proudly said, "Look, this is the one we decorated with fluorocarbon aluminum veneer. How about it? Isn't it very handsome

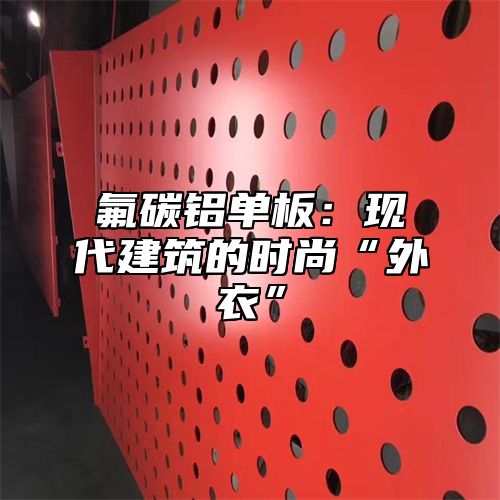

At first glance, it's quite interesting. This fluorocarbon aluminum veneer is installed on the building, with bright colors and rich texture, as if putting a fashionable "coat" on the building. If you take a closer look, you will find that this material can also customize colors according to your needs, it's really free to do whatever you want.

The benefits of fluorocarbon aluminum veneer are not limited to this. It has good weather resistance, is not afraid of wind and rain, and is durable. In the scorching summer, it can also reflect sunlight, lower indoor temperature, and save air conditioning energy. And in the cold winter, it can also isolate the cold wind, making you warm like spring at home. It has to be said that this fluorocarbon aluminum veneer is simply a thoughtful little cotton jacket for architecture.

Of course, good things always attract envy, jealousy, and hatred. Some businesses use inferior aluminum plates as fluorocarbon aluminum veneers in order to make huge profits. I would like to remind everyone that when choosing fluorocarbon aluminum veneer, they must keep their eyes open and identify authentic brands. Otherwise, your "coat" may turn into a "torn cotton jacket".

How is fluorocarbon aluminum veneer manufactured? Below, I will unravel this mystery for everyone.

The selection of materials is crucial. The main raw material for fluorocarbon aluminum veneer is aluminum alloy. When choosing aluminum ingots, we must strictly control their quality to ensure high purity and no impurities.

Let's proceed with the processing. Cut aluminum ingots into plates of a certain size, and process them through rolling, leveling, and other processes to achieve the specified thickness of the aluminum plate. In this process, we need to pay attention to controlling the rolling force and temperature to avoid affecting the performance of the aluminum plate.

We perform surface treatment. Anodize the flat aluminum plate to form a dense oxide film on its surface, improving its corrosion resistance. Afterwards, we coated the aluminum plate with fluorocarbon coating to present different colors and textures.

We will perform cutting, welding, punching and other processing on the coated aluminum plate to make it a fluorocarbon aluminum veneer that can be installed on buildings.

How about it, is this process quite complicated? However, it is precisely these rigorous processes that have made fluorocarbon aluminum veneer the fashionable "outerwear" of modern architecture.

Fluorocarbon aluminum veneer, as a new type of building material, has gained increasing popularity among consumers due to its excellent performance and unique fashion sense. In the future, I believe it will become the "coat" of more buildings, making our city more beautiful.

I want to say that life is like this fluorocarbon aluminum veneer, which requires both fashion and quality. Only in this way can we live a beautiful life. Friends, do you think so?