Industry information

Industry information

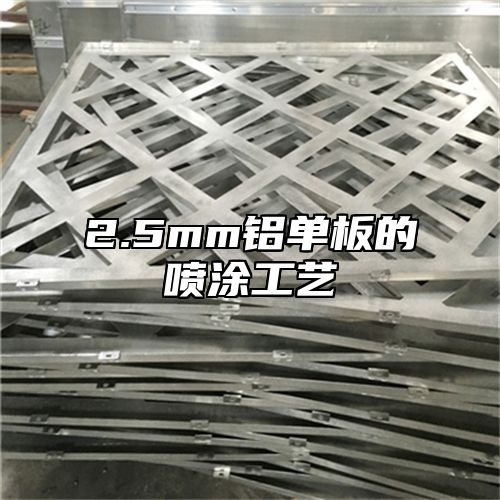

With the development of the architectural decoration industry, the application of 2.5mm thick aluminum veneer is becoming increasingly widespread. In addition to conventional surface treatment methods, spray coating has also become one of the commonly used surface treatment methods. The following will provide a detailed introduction to the spraying process of 2.5mm thick aluminum veneer.

1、 Principles of Spray Coating Process

Spray coating process is a technique that uses compressed air or liquid to evenly spray paint onto the surface of a substrate. In the spraying process of 2.5mm thick aluminum veneer, the first step is to prepare a coating with color and texture, and then evenly spray the coating onto the aluminum veneer to be treated by compressed air or liquid, finally forming the desired decorative effect.

2、 Spray coating process flow

1. Prepare paint: Design and produce according to needs to ensure clarity and accuracy of color and texture.

2. Cleaning the substrate: Use appropriate cleaning agents to clean the substrate to remove surface dirt and grease.

3. Primer spraying: Spray a layer of primer on the surface of the substrate to enhance the adhesion and durability of the coating.

4. Intermediate coating spraying: After the primer dries, spray the intermediate coating to increase the thickness and texture of the coating.

5. Topcoat spraying: After the intermediate coating dries, spray the topcoat to achieve the final color and texture effect.

6. Follow up processing: Perform subsequent processing as needed, such as polishing, drying, etc., to enhance the decorative effect.

3、 Precautions

When spraying 2.5mm thick aluminum veneer, the following points should be noted:

1. It is necessary to choose and match according to actual needs and usage environment to ensure that the decorative effect meets the expected requirements.

2. When selecting materials and processing, attention should be paid to the matching of quality and specifications to avoid situations where problems cannot be solved.

3. During the construction process, it is necessary to pay attention to the implementation of safety protection measures to prevent accidental injury accidents.

4、 Summary

The spraying process of 2.5mm thick aluminum veneer is one of the important factors affecting its application effect. During the spraying process, it is necessary to pay attention to the preparation work, correct selection and matching of materials, and strict quality inspection to ensure that the product meets the expected requirements. At the same time, it can also be reasonably matched and used according to market demand and aesthetic standards to enhance the beauty and added value of the product.