Industry information

Industry information

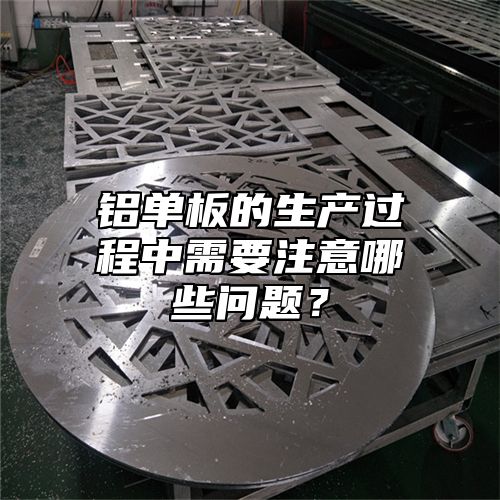

Aluminum veneer is a common building material with advantages such as lightweight, corrosion resistance, and easy processing. When producing aluminum veneer, multiple issues need to be noted to ensure its quality and performance. Below, we will provide a detailed introduction to the issues that need to be noted during the production process of aluminum veneer.

1、 Selection of raw materials

The main raw materials for aluminum veneer are aluminum alloy sheets and surface treatment materials. When selecting raw materials, it is necessary to consider factors such as quality, specifications, and thickness, and conduct strict inspection and testing to ensure that they meet design and usage requirements.

2、 Selection of Production Process

The production process of aluminum veneer includes various methods such as roll forming, spraying, anodizing, etc. When choosing a production process, it is necessary to comprehensively consider the characteristics and uses of aluminum veneer, and select the most suitable production process to improve production efficiency and product quality.

3、 Equipment selection

The production of aluminum veneer requires the use of various equipment, such as roller presses, spraying equipment, anodizing equipment, etc. When selecting equipment, it is necessary to consider factors such as performance, reliability, and safety, and conduct strict inspection and testing to ensure that it meets design and usage requirements.

4、 Control of process parameters

In the production process of aluminum veneer, multiple process parameters need to be controlled, such as temperature, pressure, time, etc. The control of these process parameters directly affects the quality and performance of aluminum veneer, therefore strict control and adjustment are required to ensure that the product meets the design and usage requirements.

5、 Quality inspection and testing

In the production process of aluminum veneer, multiple quality inspections and tests are required to ensure that the product's quality and performance meet the design and usage requirements. These inspections and tests include multiple aspects such as visual inspection, dimensional measurement, strength testing, corrosion resistance testing, etc.

6、 Environmental Protection

The production process of aluminum veneer will generate certain pollutants such as wastewater, exhaust gas, and waste residue. In order to protect the environment and human health, corresponding measures need to be taken for treatment and disposal, such as wastewater treatment, exhaust gas purification, etc.

In the production process of aluminum veneer, multiple issues need to be paid attention to, including the selection of raw materials, production processes, equipment, control of process parameters, quality inspection and testing, and environmental protection. Only by strictly controlling these issues can we ensure that the quality and performance of aluminum veneer meet the design and usage requirements.