Industry information

Industry information

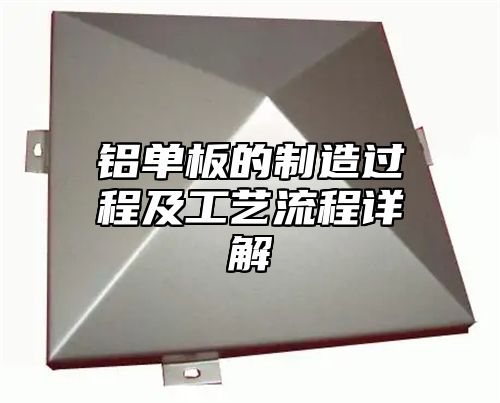

Aluminum veneer is a new type of building material that has advantages such as lightweight, high strength, and corrosion resistance. It is widely used in fields such as building curtain walls and interior decoration. The manufacturing process and process flow of aluminum veneer are also important factors affecting its quality and performance. What is the manufacturing process and process flow of aluminum veneer?

1、 Raw materials for aluminum veneer

The main raw material for aluminum veneer is aluminum, generally using series such as 1100, 3003, 5052 aluminum. After pre-treatment, these aluminum materials can be obtained into aluminum plates of different specifications and surface states. Additional auxiliary materials such as polyester resin and silicone sealant need to be added to meet different usage requirements.

2、 The manufacturing process of aluminum veneer

The manufacturing process of aluminum veneer mainly includes the following steps:

1. Aluminum processing

Aluminum processing is the fundamental step in the manufacturing of aluminum veneer. Firstly, the aluminum material needs to be cut into the required size and shape, and then processed using a rolling machine or roller press to achieve the desired thickness and flatness.

2. Surface treatment

Surface treatment of aluminum is one of the key steps to ensure the quality of aluminum veneer. Aluminum surfaces are usually treated using methods such as anodizing, spraying, and rolling to improve their corrosion resistance, hardness, and wear resistance, while also beautifying the appearance of aluminum veneers.

3. Coating

Coating is one of the important processes in the manufacturing of aluminum veneer. Polyester resin or fluorocarbon paint are usually used to coat aluminum veneers to increase their waterproof, anti fouling, and weather resistance properties.

4. Composite processing

Composite processing is the process of composite processing of different materials of sheets or coils. In the manufacturing of aluminum veneer, materials such as honeycomb core or corrugated core are usually used for composite processing to increase the strength and stiffness of the aluminum veneer.

3、 Process flow of aluminum veneer

The process flow of aluminum veneer mainly includes the following steps:

1. Design and drafting

Design aluminum veneer drawings and solutions that meet customer requirements and actual on-site conditions.

2. Raw material procurement

According to the design plan and requirements, procure the necessary raw materials and auxiliary materials.

3. Production and processing

According to the design plan and process flow, carry out aluminum processing, surface treatment, coating, and composite processing.

4. Quality inspection

Conduct quality inspection on the produced aluminum veneer to ensure that it meets relevant standards and requirements.

5. Packaging and transportation

Packaging and transportation of qualified aluminum veneers for timely delivery to customer sites.