Industry information

Industry information

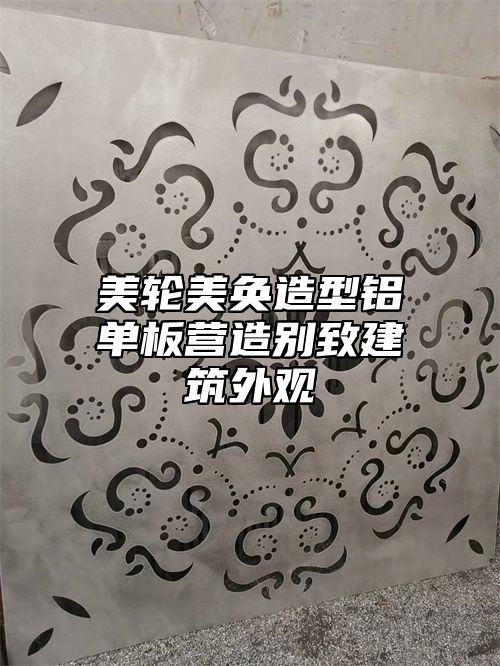

With the continuous development and innovation of the architectural decoration industry, beautiful shaped aluminum veneer, as a new type of building material, is also receiving increasing attention in exterior design. This article will provide a detailed introduction on how to create a unique architectural appearance through beautifully designed aluminum panels, high-quality materials, and manufacturing processes.

1、 Exquisite design

1. Unique styling design

The design of beautifully shaped aluminum veneer should have a unique styling effect and can be personalized according to different occasions and needs. For example, it can be applied to commercial spaces, hotel lobbies, and other places to create unique decorative effects.

2. Application of artistic design elements

The application of artistic design elements is one of the important means for the beautiful design of aluminum veneer. For example, abstract patterns, natural elements, etc. can be incorporated into the shape of aluminum veneer to increase its artistic and decorative value.

3. Application of Lighting Design

Lighting design is a very important design technique that can create different spatial atmospheres through different lighting effects. In the design of beautifully shaped aluminum veneers, lighting design can play a very important role, which can increase the artistic and decorative value of aluminum veneers, while also enhancing their sense of space and hierarchy.

2、 High quality materials

1. High strength aluminum alloy sheet

The main material of beautifully shaped aluminum veneer is high-strength aluminum alloy sheet, which has the advantages of lightweight, high strength, and corrosion resistance, and can meet various needs of building decoration.

2. Fine surface treatment

In addition to high-strength aluminum alloy sheets, beautifully shaped aluminum veneers also require fine surface treatment to improve their waterproofing and durability. The common surface treatment methods currently include anodizing, spraying, electrophoretic coating, etc.

3、 Production process

1. CNC cutting and laser drilling

During the production process, it is necessary to perform CNC cutting and laser drilling on the aluminum veneer for installation and use. Traditional cutting and drilling methods often suffer from problems such as low precision and low efficiency, while modern CNC cutting and laser drilling technologies can effectively solve these problems, improve production efficiency and product quality.

2. Fine carving and splicing

The design of beautifully shaped aluminum veneer should also have a certain degree of artistic value, which can be created through techniques such as fine carving and splicing to create more exquisite styling effects. It can also be combined with other decorative materials to create a richer visual effect.

As a new type of building material, aluminum veneer with beautiful shapes is also receiving increasing attention in terms of exterior design. In the future development, with the continuous progress and innovation of technology, it will have a wider and more diverse range of application scenarios.