Industry information

Industry information

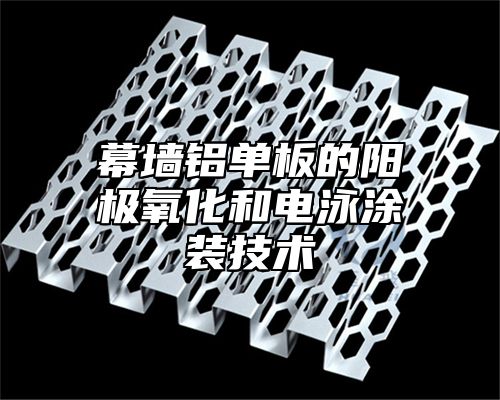

As a common building decoration material, the anodizing and electrophoretic coating technology of curtain wall aluminum veneer has a significant impact on the surface treatment effect, durability, and aesthetics of the product. Below, we will provide a detailed introduction to the anodizing and electrophoretic coating techniques for curtain wall aluminum veneers.

1、 Anodizing technology

In terms of anodizing technology for curtain wall aluminum veneer, it mainly involves the following aspects:

1. Material selection: By selecting curtain wall aluminum veneer materials with good surface treatment properties, such as aluminum alloys, the surface can be anodized to enhance its corrosion resistance and aesthetics.

2. Process flow: Through specific processes such as cleaning, electrolysis, water washing, dyeing, etc., the coating is evenly applied to the surface of the curtain wall aluminum veneer to achieve the desired color and texture.

3. Quality control: Through strict quality control measures such as testing coating thickness, hardness, and other indicators, ensure that the surface treatment effect obtained meets the requirements.

2、 Electrophoretic coating technology

In terms of electrophoretic coating technology for curtain wall aluminum veneer, it mainly involves the following aspects:

1. Material selection: By selecting curtain wall aluminum veneer materials with good surface treatment properties, such as aluminum alloys, it is possible to achieve electrophoretic coating treatment on the surface, thereby enhancing its corrosion resistance and aesthetics.

2. Process flow: Through specific processes such as cleaning, electrolysis, electrophoretic coating, etc., the coating is evenly applied to the surface of the curtain wall aluminum veneer to achieve the desired color and texture.

3. Quality control: Through strict quality control measures such as testing coating thickness, hardness, and other indicators, ensure that the surface treatment effect obtained meets the requirements.

3、 Conclusion and Suggestions

When selecting and using curtain wall aluminum veneer, attention should be paid to the considerations of anodizing and electrophoretic coating technology to meet the requirements of the overall surface treatment effect, durability, and aesthetics of the building. It is also necessary to pay attention to the selection and control of material quality, process level, and other aspects to ensure the quality and effect of the curtain wall aluminum veneer. For suppliers, they can provide higher quality curtain wall aluminum veneer products and services by continuously optimizing product design, strengthening technological research and development, and meeting the needs of different customers. We also need to strengthen our awareness of environmental protection and responsibility, and actively promote the application and development of green environmental protection concepts in the curtain wall aluminum veneer industry.