Industry information

Industry information

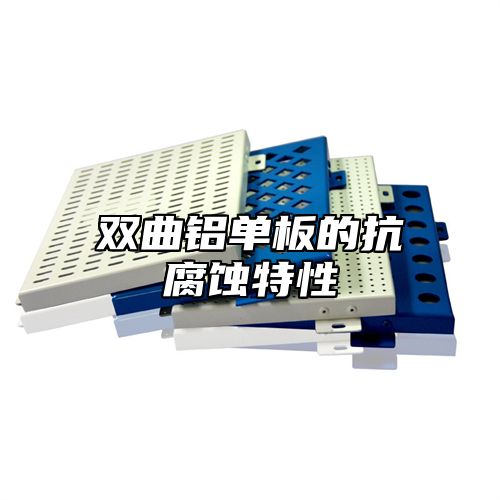

Hyperbolic aluminum veneer, as a new type of building material, has a unique design sense and decorative effect, and its corrosion resistance is also one of its important characteristics. The corrosion resistance characteristics of hyperbolic aluminum veneer are mainly manifested in its surface treatment. Below, we will introduce in detail the corrosion resistance characteristics of hyperbolic aluminum veneer.

1、 Anodizing process

The most commonly used surface treatment for hyperbolic aluminum veneer is anodizing process. This process enhances the corrosion resistance and wear resistance of aluminum by forming an oxide film on its surface. This oxide film not only prevents the aluminum surface from being oxidized, but also resists the erosion of acidic and alkaline substances. This process can also create different colors and textures, increasing the artistic and decorative value of hyperbolic aluminum veneer.

2、 Electrophoretic coating process

In addition to anodizing process, hyperbolic aluminum veneer can also be surface treated using electrophoretic coating process. This process deposits fluorocarbon coating on the surface of aluminum through electrolysis, forming a strong protective film. This coating not only has excellent corrosion resistance, but also excellent weather resistance and UV resistance. This process can also form various colors and patterns, increasing the artistic and decorative value of hyperbolic aluminum veneer.

3、 Powder spraying process

In addition to anodizing and electrophoretic coating processes, hyperbolic aluminum veneer can also be surface treated using powder coating technology. This process forms a strong protective film by spraying powder onto the surface of aluminum. This coating not only has excellent corrosion resistance, but also excellent weather resistance and UV resistance. This process can also form various colors and patterns, increasing the artistic and decorative value of hyperbolic aluminum veneer.

4、 Conclusion and Suggestions

The corrosion resistance of hyperbolic aluminum veneer is mainly manifested in its surface treatment. High quality surface treatment can ensure the corrosion resistance and wear resistance of hyperbolic aluminum veneer, thereby ensuring its aesthetics and service life. When selecting suppliers for hyperbolic aluminum veneer products and services, it is important to pay attention to their surface treatment technology and quality, and choose suppliers with high-quality and stable products and services. We also need to strengthen our awareness of environmental protection and responsibility, and actively promote the application and development of green environmental protection concepts in the construction industry.