Industry information

Industry information

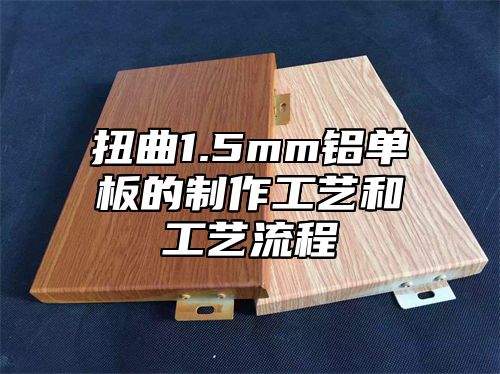

Twisted 1.5mm aluminum veneer is a new type of building decoration material with advantages such as lightweight, high strength, and corrosion resistance. Its manufacturing process and workflow are key factors in ensuring its quality and aesthetic appeal. Below, we will provide a detailed introduction to the manufacturing process and workflow of twisted 1.5mm aluminum veneer.

1、 Raw material preparation

1. Aluminum material: High quality aluminum alloy material is the basis for twisting 1.5mm aluminum veneer. It is recommended to choose aluminum alloy materials such as AA1100, 3003, 5052 that meet national standards.

2. Surface treatment: The surface treatment of twisted 1.5mm aluminum veneer is also an important part of the manufacturing process. The commonly used surface treatment methods currently include spraying, rolling, and anodizing, among which anodizing treatment can improve the corrosion resistance and aesthetics of aluminum veneer.

2、 Cutting and processing

1. Cutting equipment: Twisting 1.5mm aluminum veneer requires precise cutting processing, so professional cutting equipment such as CNC cutting machines are needed.

2. Cutting accuracy: The dimensional accuracy requirement for twisted 1.5mm aluminum veneer is relatively high, generally within ± 0.1mm. During the cutting process, attention should be paid to maintaining the stability of the equipment and the skill level of the operators.

3、 Bending processing

1. Bending equipment: Twisting 1.5mm aluminum veneer requires bending processing, so professional bending equipment such as CNC bending machines are needed.

2. Bending angle: The bending angle required for twisting 1.5mm aluminum veneer is relatively high, generally within ± 0.1 °. During the bending process, it is necessary to pay attention to maintaining the stability of the equipment and the skill level of the operators.

4、 Welding processing

1. Welding equipment: Twisting 1.5mm aluminum veneer requires welding processing, so professional welding equipment such as high-frequency welding machines are needed.

2. Welding process: The welding process for twisted 1.5mm aluminum veneer includes two methods: spot welding and seam welding. Spot welding is mainly used for small-sized aluminum veneers, while seam welding is mainly used for large-sized aluminum veneers.

5、 Surface treatment

1. Anodizing: Twisted 1.5mm aluminum veneer after welding processing requires surface treatment, among which anodizing treatment is the most common. This processing method can improve the corrosion resistance and aesthetics of aluminum veneer.

6、 Quality inspection packaging

1. Quality inspection: Twisted 1.5mm aluminum veneer needs to undergo quality inspection after production to ensure that its quality meets the standard requirements.

2. Packaging: Twisted 1.5mm aluminum veneer that has passed quality inspection needs to be packaged to protect it from damage or contamination.

7、 Summary

The production process and workflow of twisted 1.5mm aluminum veneer are one of the key factors to ensure its quality and aesthetics. Through reasonable preparation of raw materials, precise cutting, precise bending, efficient welding, high-quality surface treatment, and strict quality inspection packaging, high-quality twisted 1.5mm aluminum veneer products can be produced, adding more beauty and artistic value to buildings.