Industry information

Industry information

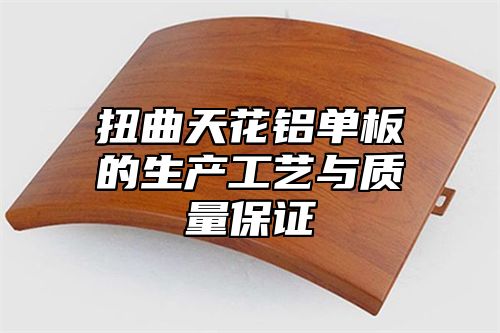

Twisted ceiling aluminum veneer, as a new type of building decoration material, has a significant impact on the quality and performance of the entire product through its production process and quality assurance. Let's take a detailed look at the production process and quality assurance of twisted ceiling aluminum veneer.

1、 Production process

1. Raw material preparation

The main raw materials for twisted ceiling aluminum veneer are high-strength aluminum alloy sheets and baked paint coatings. Strict inspection and screening of raw materials are required before production to ensure that their quality meets the requirements.

2. Cutting and processing

Cut and process high-strength aluminum alloy sheets according to design requirements to obtain the required size and shape. Cutting and processing require high-precision CNC equipment to ensure cutting accuracy and surface quality.

3. Forming and processing

The cut high-strength aluminum alloy sheet is subjected to forming processing, including bending, stamping, die casting, and other processes, to form the desired component shape and structure. Advanced equipment and technology are required for molding processing to ensure the accuracy and quality of the components.

4. Surface treatment

Surface treatment of high-strength aluminum alloy components after forming processing, including cleaning, removal of oxide layer, spraying paint and other processes, to improve surface quality and anti-corrosion performance.

5. Assembly and installation

Assemble and install the processed components to form a twisted ceiling aluminum veneer structure as a whole. Assembly and installation require the use of professional equipment and technology to ensure the stability and safety of the overall structure.

2、 Quality Assurance

1. Strict procurement and inspection of raw materials

The production process of twisted ceiling aluminum veneer requires the use of high-quality raw materials, so the company will conduct strict inspection and screening of the purchased raw materials to ensure that their quality meets the requirements.

2. Improved production processes and equipment

The company has advanced production technology and equipment that can meet the production needs of twisted ceiling aluminum veneer with different specifications and requirements. The company will continue to update and upgrade its production processes and equipment to improve product quality and production efficiency.

3. Strict quality control standards

The company has established strict quality control standards, including multiple stages such as raw material inspection, production process control, and finished product inspection, to ensure that each stage meets quality requirements. The company will also conduct regular sampling and comprehensive testing of products to ensure that product quality meets national standards and customer requirements.

4. Timely and effective after-sales service

The company provides timely and effective after-sales service, including solutions to product quality issues, technical consulting, and other services. Through high-quality after-sales service, customer satisfaction and trust can be improved, enhancing the company's market competitiveness.

Twisted ceiling aluminum veneer, as a new type of building decoration material, has a significant impact on the quality and performance of the entire product through its production process and quality assurance. Only through strict production processes and quality assurance measures can high-quality twisted ceiling aluminum veneer products be produced, providing customers with better service and experience.